NASC Aerospace Manufacturing

NASC Aerospace Manufacturing

Decades of Manufacturing Excellence

Navmar Applied Sciences Corporation (NASC) has established a venerated reputation in the Aerospace industry by offering a clear-cut and efficient path from the initial product concept to its ultimate release and application. From its inception, NASC has brought its substantial design and manufacturing talents and customer-focused approach to bear on vital initiatives for both the Department of Defense and civilian entities.

Decades of Manufacturing Excellence

Navmar Applied Sciences Corporation (NASC) has established a venerated reputation in the Aerospace industry by offering a clear-cut and efficient path from the initial product concept to its ultimate release and application. From its inception, NASC has brought its substantial design and manufacturing talents and customer-focused approach to bear on vital initiatives for both the Department of Defense and civilian entities.

A Full Range of Manufacturing Services

NASC offers expertise in a broad range of product design, engineering, prototype, production, and manufacturing services. These competencies encompass a wide spectrum of traditional machining, woodworking, sheet-metal working, joining, composite layup, assembly, and integration capabilities to meet the diverse requirements associated with today’s rapid prototyping and manufacturing.

Our diverse workforce has the capability to prepare CAD and 3D solid/surface models and change the raw stock to military-grade products. A dedicated team of engineers, technicians, craftspeople, production experts and machinists provides cost-effective and efficient solutions for the most challenging projects. NASC possesses the necessary staff, equipment, and resources to provide a 100% solution that meets the requirements of both our government and commercial customers.

A Full Range of Manufacturing Services

NASC offers expertise in a broad range of product design, engineering, prototype, production, and manufacturing services. These competencies encompass a wide spectrum of traditional machining, woodworking, sheet-metal working, joining, composite layup, assembly, and integration capabilities to meet the diverse requirements associated with today’s rapid prototyping and manufacturing.

Our diverse workforce has the capability to prepare CAD and 3D solid/surface models and change the raw stock to military-grade products. A dedicated team of engineers, technicians, craftspeople, production experts and machinists provides cost-effective and efficient solutions for the most challenging projects. NASC possesses the necessary staff, equipment, and resources to provide a 100% solution that meets the requirements of both our government and commercial customers.

NASC machinists utilize the latest technology in Computer Numeric Control (CNC) manufacturing equipment

NASC employs multiple CNC milling and turning machines to create molds, prototypes, and production components. Known for our ability to provide customized solutions, we can quickly develop and cost-effectively produce highly complex parts while maintaining the dimensional tolerances you require. Whether you need a first-run prototype or a production component, NASC will custom design or build to your unique specifications. You can depend on NASC to provide high-quality, machined components from the initial concept to final assembly.

Vacuum Bag Molding

Vacuum bag molding is a layup method used by our knowledgeable technicians to improve the mechanical properties of a hand layup (two or more layers of fiber reinforcement bonded with a resin). A vacuum is created to force out trapped air and excess resin, compacting the laminates during the curing stage.

Programmable Curing Oven

NASC offers large oven curing within our composite facility. NASC’s custom composite curing oven and process control system has the capability to cure the most advanced composite materials and resin systems used throughout the industry.

Component Finishing

NASC has a large sanding, polishing, and finishing area that enables our trained team of professionals to provide superior product finishes on both large and small composite components. We offer multiple finishing types including automotive, aerospace, and powder coating.

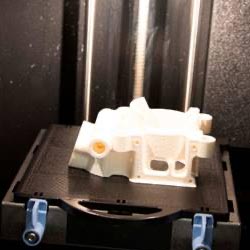

Rapid Prototyping

The diverse capabilities within our facilities allow us to manufacture prototype and production quantities. Our proven design methods and procedures reduce the cost of manufacturing parts and assemblies. By using our comprehensive inventory of 3D printers for additive manufacturing, NASC has the capability to quickly fabricate parts from SLA and ABS layers.

Assembly Design

At NASC, we utilize fundamental Design for Assembly techniques and methodologies to engineer and reverse engineer a product and to support the effectiveness of new product design and development. Our manufacturing managers and design engineers design with an “ease of assembly” approach. This ensures that final assembly is simple and efficient thus reducing time and cost.

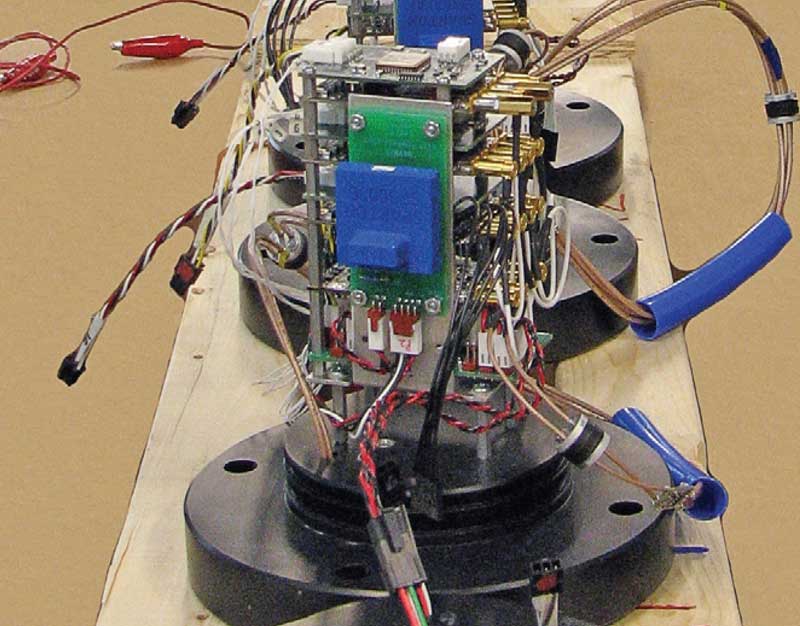

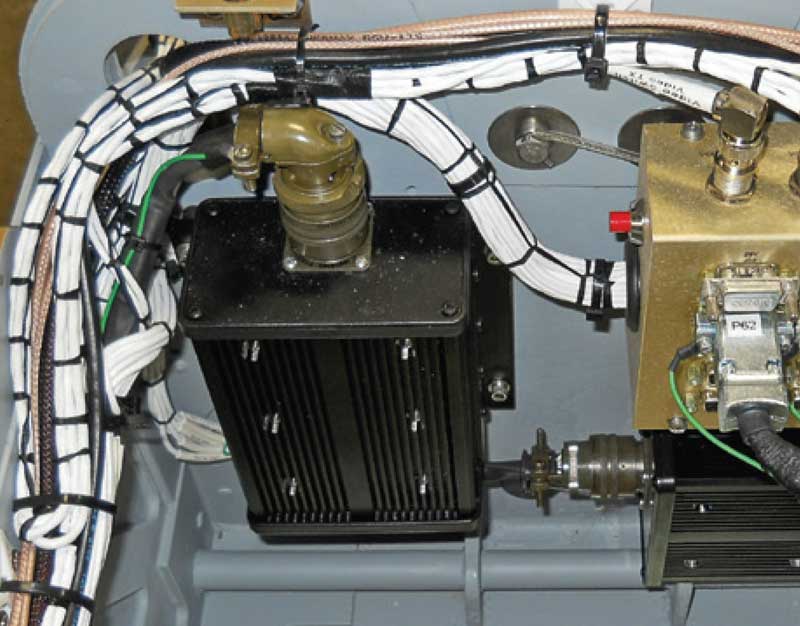

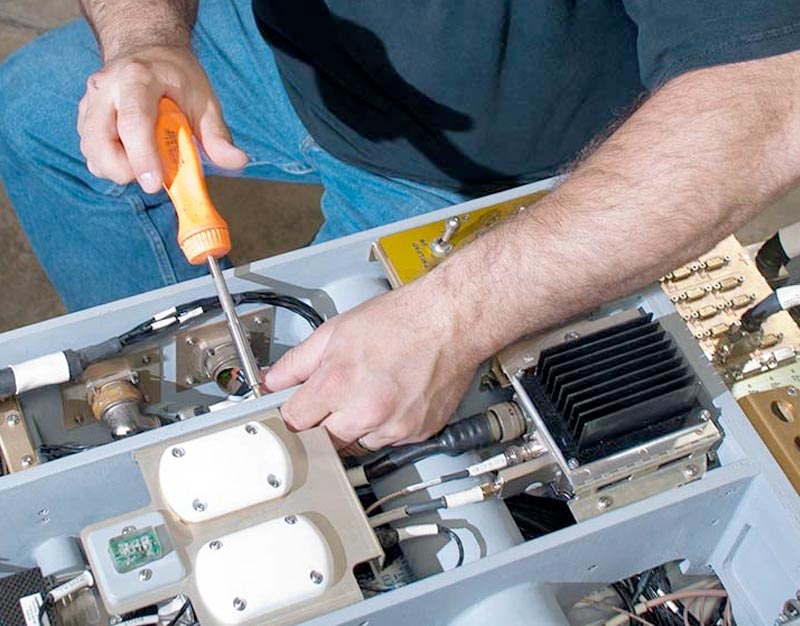

Electrical Assemblies

NASC’s electrical assembly process consists of our highly skilled technicians reading and interpreting wire schematics and drawings to build, test, and repair electrical equipment, tools, components, wire harnesses, control panels, custom electronic products, and assemblies. NASC technicians are experts in building unmanned aircraft avionics, military systems, and computer command and control products. Our technical staff prides themselves in producing quality work on schedule and within budget.

Wire Harness Layout & Assembly

- Automotive & Aircraft

- Industrial & Commercial

- Control Panels

Wire Harness Kitting

- Cut to Length

- Identification Labels

- Package Assemblies

Wire Harness Testing

- Hi-Potential Testing

- Resistance Testing

Circuit Card Design & Assembly

- Through Hole

- Simple Surface Mount

Mechanical Assemblies

NASC has years of valuable experience constructing mechanical components and sub-assemblies. We complete custom products in an assembly line or work center environment. Our mechanical assembly process is tailored to our customers’ product needs and adheres to our established quality assurance requirements. Strict procedural guidelines are followed in the assembly process ensuring components are handled once, oriented once, and attached to the assembly in an efficient order. This methodology achieves the most cost-effective assembly times and highest product quality. NASC can assist companies by applying these principles early in the design process to ensure that the product is built in the most logical order.

Product Development

NASC designers utilize SolidWorks 3D modeling software to develop and maintain configuration control of technical data for both system design and product manufacturing. With our solid modeling capability, we can ensure that parameters such as fit between assemblies and formability are within specifications.

Product Development

NASC designers utilize SolidWorks 3D modeling software to develop and maintain configuration control of technical data for both system design and product manufacturing. With our solid modeling capability, we can ensure that parameters such as fit between assemblies and formability are within specifications.

Aircraft and UAV Manufacturing

From component parts to full-scale design and production of Unmanned Aerial Vehicle (UAV) platforms, NASC can be the expert source for your manufacturing and modification needs. We specialize in building Unmanned Aircraft Systems (UAS), UAVs, and ground control systems.

NASC provides assembly and integration of avionics, sensors, and other related electro-mechanical products for government, industry, and academia. We also integrate system inputs and outputs within the network environment between the UAS ground control station, and other communication environments. NASC provides domestic and international installation services for permanent and semi-permanent unmanned air systems operations.

NASC is a Service Disabled Veteran Owned Small Business for Aircraft Manufacturing (NAICS Code 336411). We are proud to be engaged in strategic and responsive efforts to assist the Department of Defense by manufacturing and maintaining the highest quality products for our warfighters.

In addition to our internal design and manufacturing initiatives, NASC has successfully supplied external design and manufacturing support for numerous companies in the aerospace industry. These products include UAV VTOL booms, payload cases, fuselage, wings, and ejection seat components.